"Improve heating efficiency with the right heat store binding."

Parallel or series stacking of wood biomass boilers - which to choose?

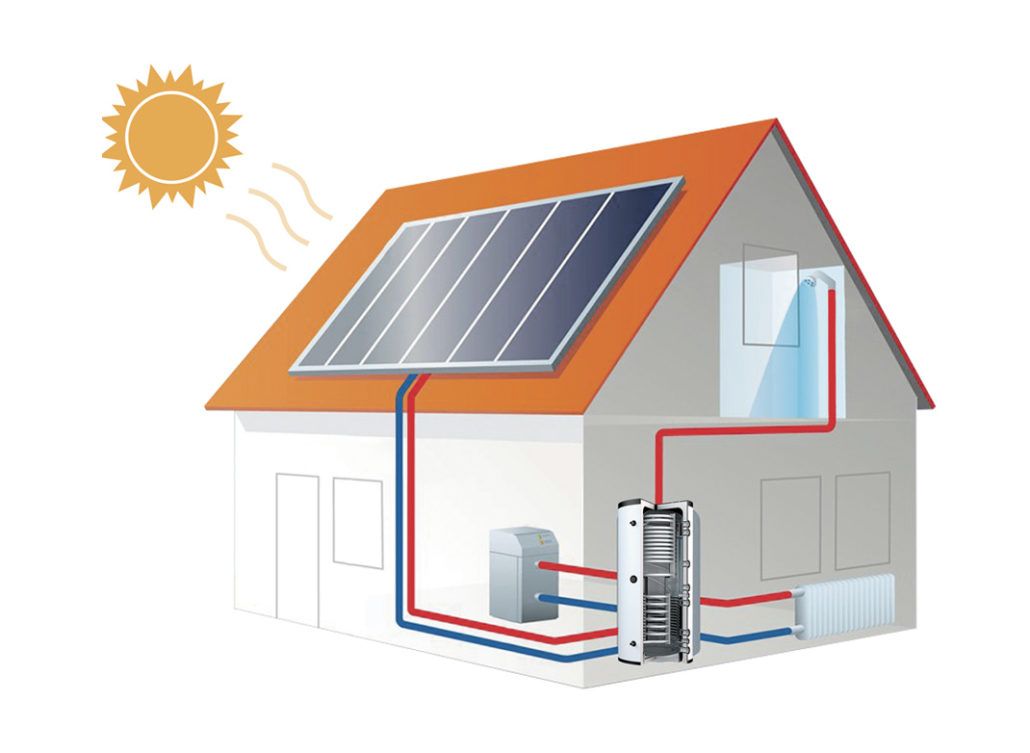

In recent years, more and more people are choosing gasification biomass boilers for their efficiency, environmental friendliness and ability to heat larger spaces. Heat storage units are also an important part of these systems, storing energy and distributing it efficiently around the house. One of the dilemmas facing installers and users is the question of how to connect the stores correctly: in parallel or in series? In this article, we will clarify the differences between the two methods and give guidelines to help you choose the right solution for your system.

What are heat storages and why are they important?

Heat storages act as large batteries for your heating system. When the boiler is running, the heat it produces does not go directly to the heating elements (radiators, underfloor heating), but is stored in the storage tanks. When the boiler stops working or reduces its output, the storage tanks release this energy into the heating system, ensuring that your home is heated continuously and efficiently.

Due to the large amount of heat stored, it is essential how these stores are connected to the boiler and to each other, as different connections can affect the efficiency of the system, its stability and the even distribution of heat.

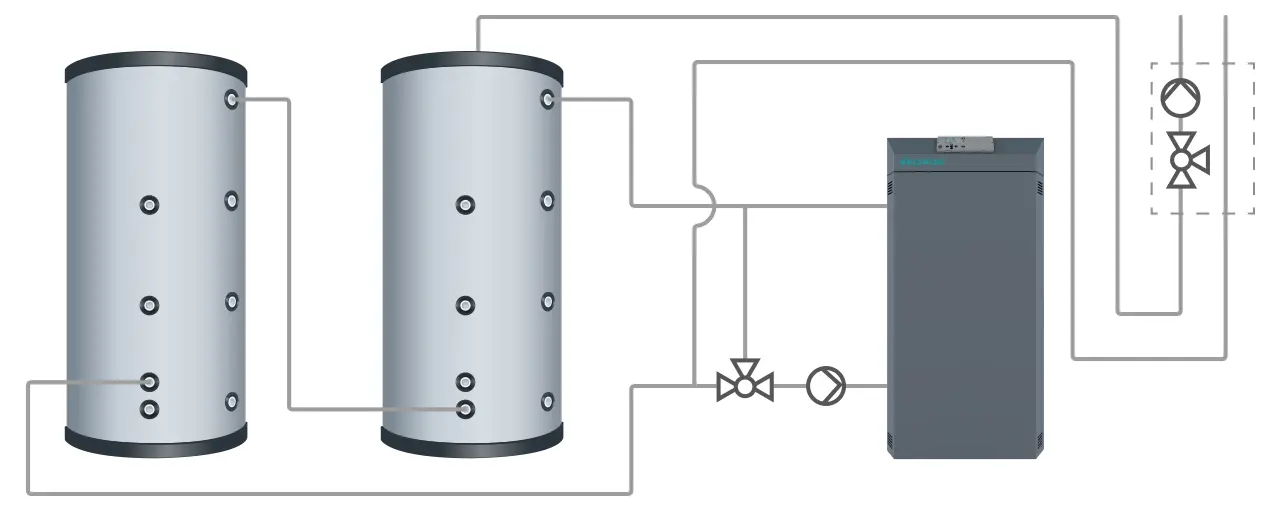

Difference between parallel and series binding of storage tanks

Parallel binding

In a parallel connection, both (or more) storage tanks are supplied with hot water from the boiler at the same time. At first sight, this solution seems simple and sensible, but it can cause some problems:

- Uneven filling

The water from the boiler will not necessarily fill both storage tanks evenly. One of the storage tanks may fill faster or to a higher temperature than the other, which can cause energy loss and inefficiency.

- Reduced efficiency

If the heat is not distributed properly, the system may overheat or the storage tanks may not reach their full capacity.

Sequential binding

In sequential coupling, the water from the boiler first fills the first storage tank and then passes to the next one. This method allows for better heat distribution and proper layering of the water, leading to higher system efficiency.

- Better layering

The water in the first storage tank is heated to a higher temperature and then transferred to the second storage tank where it cools. This ensures optimum energy utilisation.

- Increased efficiency

The series connection allows a more stable and longer heat supply, which is particularly important in systems with large storage tanks where you want to maximise the heat produced by the boiler.

Why is it essential to bind the trays correctly?

Correctly tying the storage tanks together has an impact on the efficiency of your heating system, fuel consumption and the comfort of heating in your home. Installers often recommend parallel binding because it is seemingly easier and quicker to do. However, it is important to follow the recommendations of the boiler manufacturer, who usually advocate sequential wiring.

Installers must take into account the furnace specifications and system requirements when choosing the method of connection, as only a properly designed system will work optimally and minimise the possibility of energy losses.

However, USERS often encounter anomalies such as constantly hot pipes even when the system is not working, which may indicate that the system is not properly designed.

Natural circulation - why can it be a problem?

In systems where unwanted natural circulation occurs (where water moves even when the system is stationary), unnecessary heat losses can occur. This can occur due to incorrect pipe installation, especially if the return pipes are positioned higher than the supply pipes. In such cases, correct valve placement is essential to prevent this circulation and to ensure that the system only operates when it is needed.

Recommendations for installers and users

For installers:

- Follow the manufacturers' recommendations when choosing a binding method.

- When tying in series, ensure correct layering of the storage tanks and prevent unwanted natural circulation by correctly positioning the valves.

- Check the hydraulic balancing of the system to ensure even heat distribution.

For users:

- Always check that installers have followed the manufacturer's specifications when installing the system.

- Look out for any hot pipes when the system is at standstill - this can be a sign of problems with natural circulation.

- Consult a professional if you are not sure whether your system is working optimally.

CONCLUSION

When deciding how to bundle storage tanks for wood biomass boilers, it is essential to understand the system operation and follow the manufacturers' recommendations. Although parallel linking is often faster to implement, Sequential coupling ensures better energy utilisation and higher efficiency. Installers and users should act in accordance with these recommendations to ensure optimum performance of heating systems and minimise energy losses.

For any further questions or advice on the correct selection and installation of heating systems, please contact us and we will be happy to help!