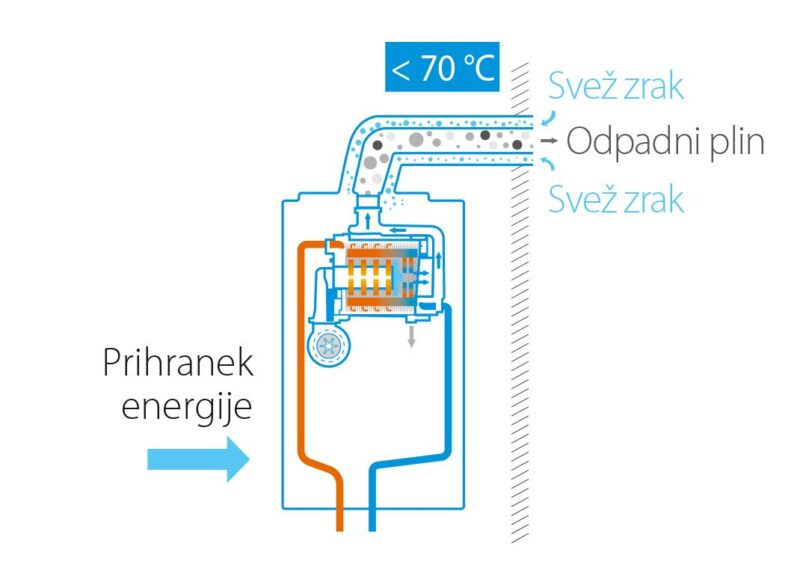

The following drawings show the difference in performance between a conventional gas boiler and a Daikin NDJ1 condensing gas boiler. The condensing technology provides an operating efficiency of 109%, resulting in energy savings.

93% efficiency

Classic combi boilers

Water escapes into the chimney as steam, so the latent heat of the water vapour is lost.

109% efficiency

Combined gas condensing boilers

The flue gases come into contact with the heating water return before being discharged into the chimney, releasing the latent heat of the steam.

Pre-mixing technology

A modulating fan is integrated to ensure a perfect mixture of air and fuel before entering the burner (air/gas mixer) for maximum combustion efficiency.

Condensation technology

Combustion of one m3 1.7 kg of water vapour is released with the flue gases, carrying latent heat. Instead of escaping through the chimney, the water vapour passes into the uniquely designed heat exchanger and warms it with its latent heat.

Condensation occurs when water vapour cools below the dew point temperature and is then discharged through the drain. Condensing technology optimises fuel utilisation, reducing NOx and CO2 emissions for a lower environmental impact, and reducing costs.